Condition:

New

Spindle Taper:

BT40

No. Of Spindles:

Single

Type:

VERTICAL

Dimension(L*W*H):

2500*2100*2360mm

Weight (T):

3.8 T

Table Size (mm):

900*400

CNC Control System:

GSK, FANUC, Siemens

Number Of Axes:

3, 4, 5

Table Travel (X) (mm):

650

Table Travel (Y) (mm):

450

Table Travel (Z) (mm):

500

Positioning Accuracy (mm):

±0.008

Repeatability (X/Y/Z) (mm):

±0.005

Range Of Spindle Speed(r.p.m):

10 - 8000 R.p.m

Spindle Motor Power(kW):

5.5

Max. Table Load(kg):

500 Kg

Feed Speed(mm/min):

1 - 24 Mm/min

Rapid Feed Speed(m/min):

1-10m/min

Min. Time Of Tool Change(s):

2

Tool Magazine Capacity:

16

Key Selling Points:

Multifunctional

Warranty:

1.5 Years

Voltage:

380/50HZ

Applicable Industries:

Machinery Repair Shops, Manufacturing Plant, Mold Making, Machine Made

Showroom Location:

Egypt, Turkey, United States, France, Germany, Brazil, Pakistan, Mexico, Russia, Morocco, Kenya, Argentina, Bangladesh, South Africa

Marketing Type:

Hot Product 2021

Machinery Test Report:

Provided

Video Outgoing-inspection:

Provided

Warranty Of Core Components:

1 Year

Core Components:

Motor

Core Components::

Bearing

Spindle Speed::

8000rpm

Application::

Metal Parts Processing

Usage::

Metal Parts Machining Center

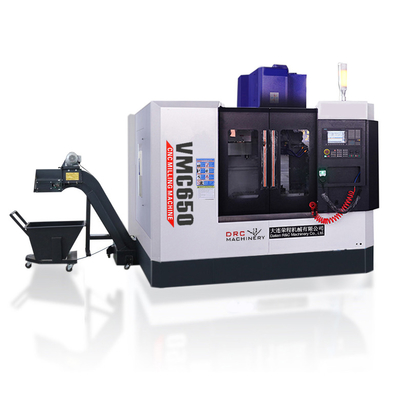

Name::

Vertical CNC Machining Center

Machine Type::

Vertical CNC Milling Machining Center

Controlling Mode::

Cnc Control Vertical Machining Center

After-sales Service Provided:

Online Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

Egypt, Turkey, United States, Italy, France, Philippines, Saudi Arabia, India, Russia, Australia, Kenya, Algeria, South Africa, Kyrgyzstan, Nigeria

Certification:

CE, ISO,TUV

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!